Table Of Contents

Regular Inspections and Maintenance

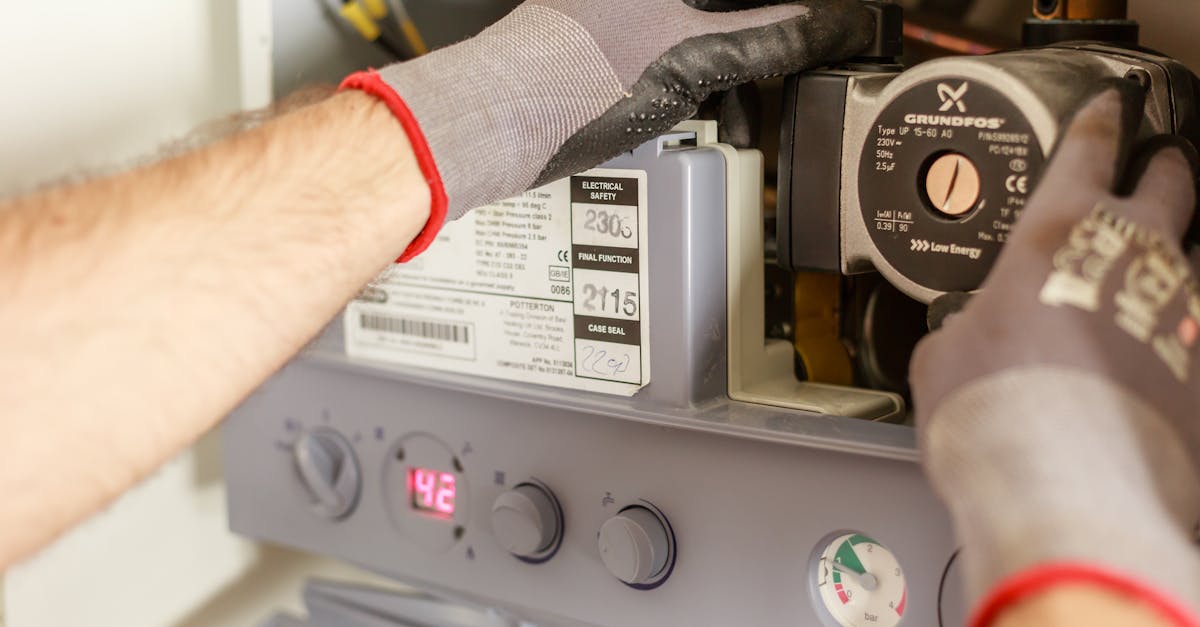

Regular inspections and maintenance are critical components in ensuring compliance with regulatory requirements for pipe installation and repair. Regular checks help identify potential issues that may arise over time, such as corrosion, leaks, or structural weaknesses. Implementing a routine inspection schedule not only enhances the longevity of the installation but also mitigates the risks associated with unforeseen failures.

Carrying out thorough inspections allows for timely interventions, which can prevent costly repairs and ensure the system operates within required standards. Detailed maintenance records should be maintained to demonstrate compliance with regulations and support any necessary reporting. Engaging qualified personnel for these inspections will contribute to a more reliable assessment of the integrity and performance of the pipe installation and repair process.

Establishing a Maintenance Schedule

A well-structured maintenance schedule is crucial in ensuring the longevity and compliance of pipe installation and repair projects. Regularly scheduled inspections help identify any potential issues before they escalate, thus reducing the risk of costly repairs and downtime. By assessing the condition of the pipes, operators can determine the appropriate maintenance actions required, whether it be routine cleaning, monitoring for corrosion, or checking connections and joints. Establishing a system that triggers maintenance tasks based on both time intervals and the performance of the pipes fosters a proactive approach to system management.

In addition to improving the life cycle of the piping systems, a thoughtful maintenance schedule aligns with regulatory requirements. Documenting each maintenance activity ensures that all actions are traceable and justifiable during audits or inspections. This not only serves to remind maintenance crews of their responsibilities but also aids in demonstrating compliance to relevant authorities. A transparent scheduling process reflects an organisation’s commitment to safety and environmental standards in conjunction with the necessary provisions for pipe installation and repair.

Documentation and Record Keeping

Proper documentation and record-keeping play a pivotal role in ensuring compliance with regulatory requirements in pipe installation and repair. Maintaining an accurate and organised record system allows organisations to track compliance checks, maintenance schedules, and any incidents that occur during operations. This documentation should include installation manuals, inspection reports, and maintenance logs, all of which must be readily accessible for audits and inspections when required.

In addition, organisations should ensure that their records are kept up to date and reflect any changes made during the pipe installation and repair process. Efficient record-keeping not only aids in regulatory compliance but also demonstrates a commitment to best practices within the industry. Implementing digital solutions can enhance the management of these documents, making it easier to retrieve and share crucial information with relevant stakeholders.

Essential Documents for Regulatory Compliance

Maintaining compliance with regulatory requirements in pipe installation and repair necessitates meticulous documentation. Essential documents include installation plans, materials specifications, and inspection reports. Each of these records serves a critical role in demonstrating adherence to safety and operational standards. Detailed logs of maintenance activities also contribute significantly to effective monitoring over time, ensuring that all installations remain compliant with evolving regulations.

Regular updates to these documents are vital to reflect any changes in regulations or operational practices. Accurate record keeping should encompass all relevant aspects, from initial design approvals to maintenance activities conducted throughout the life cycle of the installation. This comprehensive documentation not only facilitates smooth inspections by regulatory bodies but also provides a clear history of the pipe installation and repair process, reinforcing accountability and transparency in operations.

Understanding Environmental Considerations

Environmental considerations play a vital role in the planning and execution of pipe installation and repair. Projects must assess potential impacts on local ecosystems, water sources, and air quality. Comprehensive environmental impact assessments can identify risks associated with disturbances during installation, including soil erosion and habitat destruction. These evaluations ensure that the necessary mitigation strategies are in place to minimise harm to the environment.

Mitigation strategies could involve implementing protective measures such as silt fencing or buffer zones around sensitive areas. It is crucial to engage with local authorities and stakeholders to gain insights into specific environmental guidelines that apply to the project. Awareness of these considerations not only helps in achieving regulatory compliance but also fosters a commitment to sustainable practices in pipe installation and repair.

Impact Assessments and Mitigation Strategies

Conducting comprehensive impact assessments is crucial in the process of pipe installation and repair. These assessments help identify potential environmental effects arising from the work, including disruptions to local ecosystems and waterways. Early identification of these impacts enables contractors to develop effective strategies that can mitigate any adverse effects. Moreover, involving environmental specialists from the outset can enhance the quality of the assessment, ensuring compliance with local regulations.

Mitigation strategies should be tailored to address the specific risks identified during the assessment phase. Implementing preventative measures, such as erosion control or sediment management, can significantly reduce environmental disturbances. Additionally, monitoring the effectiveness of these strategies throughout the installation and repair process is essential for ensuring long-term compliance. Clear communication with regulatory bodies and stakeholders fosters transparency and supports ongoing adherence to environmental standards.

FAQS

Why are regular inspections important in pipe installation?

Regular inspections are crucial as they help identify any potential issues early, ensuring the pipe system remains compliant with regulatory requirements and operates efficiently.

How can I establish an effective maintenance schedule for pipe systems?

An effective maintenance schedule can be established by assessing the specific needs of the pipe system, considering factors such as usage frequency, environmental conditions, and regulatory requirements, to determine appropriate intervals for inspections and maintenance tasks.

What essential documents should I keep for regulatory compliance in pipe installation?

Essential documents for regulatory compliance include installation records, inspection reports, maintenance logs, permits, and any correspondence with regulatory bodies. Keeping these documents organised and accessible is crucial for demonstrating compliance.

What are the environmental considerations to keep in mind during pipe installation?

Important environmental considerations include assessing the potential impact on local ecosystems, ensuring compliance with environmental regulations, and implementing mitigation strategies to reduce any adverse effects during and after installation.

How can I conduct an effective impact assessment for pipe installation?

An effective impact assessment involves evaluating the potential environmental, social, and economic effects of the pipe installation project. This includes engaging stakeholders, collecting relevant data, and developing mitigation strategies to address identified impacts.