Table Of Contents

Applying Plumber's Tape

Plumber's tape, also known as Teflon tape, is an essential tool in pipe installation and repair. This material helps create a watertight seal on threaded joints, preventing leaks that can cause damage over time. When applied correctly, plumber's tape can significantly enhance the effectiveness of the connection, making it an invaluable asset for any plumbing job. It is particularly useful for joints in areas where flexibility may be needed, as it accommodates slight adjustments without compromising the seal.

To apply plumber's tape properly, start by ensuring that the threads of the pipe are clean and free from debris. Begin wrapping the tape in a clockwise direction, overlapping each layer slightly as you go. Aim for about three to five wraps, depending on the thickness of the tape and the size of the joint. Avoid wrapping too tightly, as this may damage the threads. Once the tape is in place, you can proceed with tightening the connection. The result should be a secure fit that helps eliminate leaks, ensuring the longevity of your plumbing system.

How to Properly Wrap Threaded Joints

Properly wrapping threaded joints is a key step in ensuring a watertight seal when undertaking pipe installation and repair. Start by cleaning the threads of the pipe and joint thoroughly. This removes any debris or old sealant material that could hinder the adhesion of the tape. Once clean, the plumber's tape should be applied, ensuring that it wraps in the same direction as the thread. This will help prevent the tape from unraveling when the joint is tightened.

When wrapping the tape, aim for two to three layers for suitable coverage without excessive bulk. Ensure the tape overlaps evenly while avoiding any tape that hangs off the end of the threads. This attention to detail is crucial for creating a secure seal that can withstand water pressure and prevent future leaks. Take care to maintain an even tension throughout the wrapping process to facilitate a snug fit when the joint is assembled.

Using Epoxy Putty for Small Leaks

Epoxy putty is an effective solution for addressing small leaks in plumbing systems. It forms a strong bond with the material of the pipe, creating a waterproof seal that can withstand pressure. This type of putty is particularly useful for minor cracks and pinhole leaks, providing a quick fix that can be applied without needing extensive tools. For those involved in pipe installation and repair, having epoxy putty on hand can save time and prevent further damage.

To use epoxy putty, start by cleaning the area around the leak thoroughly. Remove any debris, rust, or grime to ensure the putty adheres properly. Knead the epoxy until it reaches a uniform colour and consistency. Apply it directly over the leak, pressing firmly to ensure a proper seal. Allow the putty to cure as per the manufacturer's instructions. This method not only stops the leak but also adds durability to the repaired section, making it a practical choice for homeowners and professionals alike.

StepbyStep Guide to Applying Epoxy

To start applying epoxy putty, ensure the area around the leak is clean and dry. Use a cloth to remove any grease, dirt, or moisture from the surface of the pipe. Cut a suitable amount of epoxy putty from the roll. Knead the putty with your fingers until it becomes a uniform colour, indicating that it is mixed properly. The putty typically has a limited working time before it starts to harden, so it's essential to be prepared and act quickly.

Once the putty is thoroughly mixed, press it firmly onto the leak or damaged area of the pipe. Use your fingers to blend the edges of the putty with the pipe to create a seamless seal. For larger gaps, layer more putty as necessary. Allow the epoxy to cure according to the manufacturer's instructions, which usually takes a few hours. Pipe installation and repair require proper techniques and materials to ensure durability and prevent future leaks.

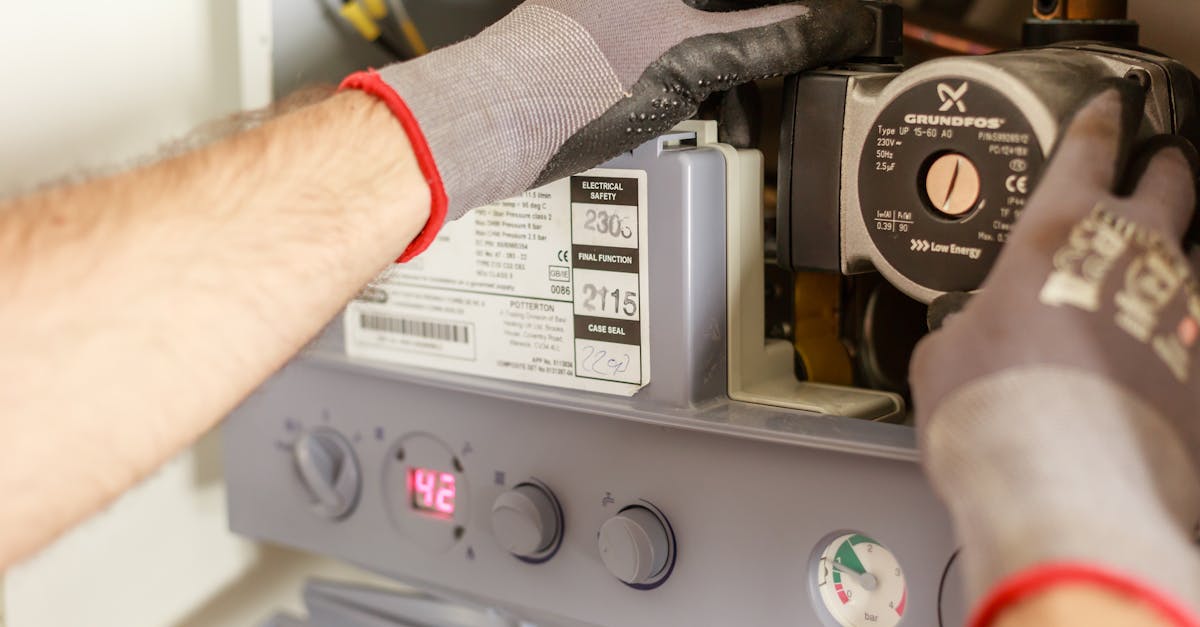

Replacing a Damaged Pipe

Assessing the overall condition of your plumbing system is crucial when dealing with leaks. If a pipe is severely corroded or damaged, patching it may only be a temporary solution. A thorough inspection can help determine whether a full replacement is necessary. Ensuring that replacement materials are compatible with the existing plumbing is vital for maintaining system integrity.

When considering pipe installation and repair, proper methods must be applied to avoid future complications. This includes selecting the right type of pipe material for your specific needs, whether it be PVC, copper, or steel. Following established industry standards during installation will enhance the longevity and reliability of your plumbing system.

When to Consider Full Replacement

Assessing the condition of your pipes is crucial in determining whether a repair will suffice or if a full replacement is necessary. If you notice persistent leaks, extensive corrosion, or structural damage, a full replacement might be the more viable option. Older pipes, particularly those made from materials like galvanised steel or lead, can pose significant risks to health and safety. In such cases, investing in new pipe installation and repair can save money in the long run and prevent future issues.

It is essential to consider the overall age and material of the plumbing system as well. Pipes that have been in place for many years often become less reliable, increasing the likelihood of further leaks or failures. If you're dealing with frequent plumbing problems and costly repairs, replacing the entire system can provide peace of mind. A comprehensive assessment by a licensed plumber can help clarify the best course of action, ensuring your pipe installation and repair is executed efficiently.

FAQS

What is plumber's tape and how does it work?

Plumber's tape, also known as Teflon tape, is a thin, white tape used to create a watertight seal on threaded pipe connections. It helps prevent leaks by filling in the gaps between the threads when wrapped correctly.

Can I use plumber's tape on all types of pipes?

Plumber's tape is suitable for most threaded metal and plastic pipes, but it's important to check if it's appropriate for your specific type of pipe. Avoid using it on compression fittings or non-threaded connections.

How do I apply epoxy putty to fix a leak?

To apply epoxy putty, start by cleaning the area around the leak, then knead the putty until it's uniform. Press it firmly over the leak and shape it as needed. Allow it to cure as per the manufacturer's instructions.

When should I consider replacing a damaged pipe?

You should consider full replacement if the pipe is extensively corroded, has multiple leaks, or if the material is outdated and prone to failure. Consulting a professional plumber can help determine the best course of action.

Are there any temporary fixes for a leaky pipe connection?

Yes, temporary fixes include using duct tape, hose clamps, or wrapping the leak with a cloth and securing it with tape. However, these solutions are not long-term and the leaky connection should be repaired properly as soon as possible.