Table Of Contents

Replace Damaged Sections of Pipe

If you encounter a leak that results from significant damage to a section of the pipe, replacing that section is essential. Start by identifying the specific location of the leak and assessing the extent of the damage. Mark the area that requires replacement before you turn off the water supply to prevent any further water spillage. It may be necessary to drain the pipe before proceeding with the replacement to ensure a clean working environment during the repair process.

Once you’ve cut out the damaged section, precise measurements are crucial for ensuring the new pipe fits seamlessly. Choose a replacement pipe that is made from compatible materials, such as PVC or copper, depending on the existing infrastructure. Pipe installation and repair demand attention to detail, so ensure all connections are secure and tightly fitted to prevent future leaks. After the new section is installed, turn the water supply back on and monitor for any signs of leakage in the newly repaired area.

How to Cut and Fit New Pipe

Cutting and fitting new pipe involves precise measurements and clean cuts to ensure a proper seal. Start by measuring the length of pipe needed, allowing for connectors and fittings. Use a pipe cutter or a hacksaw for straight cuts, making sure to remove any burrs from the edges using a deburring tool. This preparation helps prevent leaks during pipe installation and repair as well as ensures that the new pipe aligns correctly with existing plumbing.

When fitting the new section of pipe, it's vital to use appropriate connectors such as couplings or elbows that match the diameter of the pipes. Apply a primer and adhesive if using PVC pipe, or thread tape for threaded metal pipes to enhance the watertight seal. Position the new pipe carefully, ensuring that it fits snugly into the connectors. Allow adequate time for adhesives to cure before turning the water supply back on. This attention to detail ensures a durable and leak-free result.

Use Pipe Sealant for Small Leaks

For minor leaks in your plumbing system, using pipe sealant can be an effective solution. This method is particularly useful for small gaps or cracks that may develop over time. Proper application of sealant can prevent water from seeping out, offering a temporary fix until a more permanent repair can be arranged. When selecting a sealant, consider the specific material of your pipes to ensure compatibility and effectiveness.

Pipe installation and repair jobs often require precision and consideration of various factors, including temperature and pressure. Ensure that the area around the leak is clean and dry before applying the sealant. Follow the manufacturer’s instructions for application. Allow adequate time for the sealant to cure before turning the water back on, which will help to maintain a secure and leak-free environment in your plumbing system.

Choosing the Right Sealant for the Job

Selecting the appropriate sealant for your plumbing needs is crucial for effective water pipe maintenance. Different types of sealants cater to various materials and applications. For instance, silicone sealants are versatile and can be used on both plastic and metal pipes. On the other hand, Teflon tape is often best suited for threaded connections. Understanding the specific requirements of your pipe installation and repair will ensure that you choose a sealant that provides a strong and lasting bond.

Before applying any sealant, it’s essential to prepare the surfaces properly. Cleaning the area around the leak will help the sealant adhere better. In cases of minor leaks, a liquid sealant can fill gaps and provide a watertight seal. For larger issues, consider using a putty or epoxy sealant, which offers a more robust solution. Selecting the right product for your situation will play a significant role in preventing future leaks and maintaining the integrity of your plumbing system.

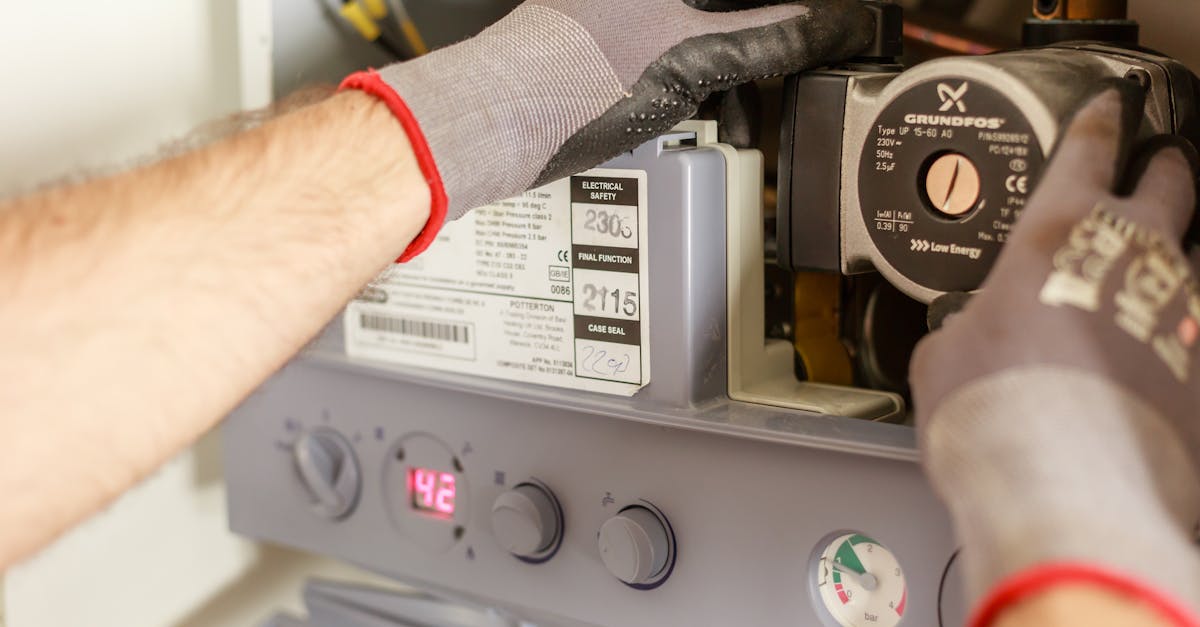

Tighten Connections and Fittings

Tightening connections and fittings should be a priority when addressing a leaking water pipe. Over time, joints can loosen due to changes in temperature, pressure fluctuations, or simple wear and tear. Inspect all visible connections closely for signs of leakage, including any dripping or moisture accumulation around the fittings. Use appropriate tools, such as pliers or wrenches, to securely tighten these connections, ensuring they are snug but not overly tight, which could cause damage.

Pipe installation and repair require an understanding of the specific materials being used. Different piping materials, such as PVC, copper, or galvanised steel, have unique properties that influence how connections should be tightened. Take care to match the tightening approach to the type of pipe, as excessive force on certain materials can lead to cracks or breakage. Regular checks and maintenance of fittings can help prevent leaks from reoccurring in the future.

Ensuring a Secure and LeakFree Joint

Ensuring a secure and leak-free joint is crucial in maintaining the integrity of your plumbing system. When working on pipe installation and repair, it is essential to ensure that all connections are tightened adequately. Use a wrench to apply the necessary torque, but be cautious not to overtighten, as this can lead to damage. Inspect the joint for any visible gaps or misalignments.

In addition to tightening connections, consider using thread seal tape or joint compound for added protection against leaks. These materials can provide an extra layer of security by filling in any small gaps that might otherwise allow water to escape. Regularly check fittings and joints as part of ongoing maintenance to catch potential issues before they develop into serious problems.

FAQS

What should I do first if I notice a leak in a water pipe?

The first step is to turn off the water supply to prevent further water damage. Once the water is off, you can assess the situation and decide whether to replace damaged sections of the pipe, use pipe sealant for small leaks, or tighten connections and fittings.

How can I tell if a section of my water pipe is damaged?

Look for visible signs such as water stains, corrosion, or dampness around the pipe. You may also notice decreased water pressure or hear water hissing from the pipe, which can indicate a leak.

What tools do I need to cut and fit a new section of pipe?

You'll typically need a pipe cutter, a measuring tape, a marker, and possibly a deburring tool to smooth the edges of the cut pipe. It's also helpful to have pipe wrenches and a fitting for connections.

Can I use any kind of sealant for small leaks?

No, it's important to choose the right sealant for the material of your pipe. For example, silicone-based sealants work well for PVC pipes, while epoxy putty is suitable for metal pipes. Always check the manufacturer's instructions.

How tight should I make the connections and fittings?

Connections should be tight enough to prevent leaks but not so tight that they cause damage to the pipe or fittings. It's best to follow the manufacturer's guidelines or use a torque wrench for precision if applicable.