Table Of Contents

Involving Qualified Professionals

Engaging qualified professionals for pipe installation and repair is crucial for maintaining the structural integrity of plumbing systems. These experts possess the necessary skills, knowledge, and experience to navigate the intricacies of compliance regulations. When professionals are involved, the risks associated with improper installation can be significantly minimised. Their understanding of local codes ensures that all work is carried out in accordance with the required standards, which helps prevent costly rectifications in the future.

Certified installers bring a wealth of practical experience to every project. Their training often includes comprehensive safety protocols and effective problem-solving strategies, which considerably enhance the quality of work performed. By enlisting their services, property owners can have peace of mind knowing that their pipe installation and repair tasks are undertaken with precision. This accountability not only aids in developing a reliable plumbing system but also fosters a safer environment overall.

Benefits of Hiring Certified Installers

Hiring certified installers for pipe installation and repair ensures adherence to industry standards and regulations. These professionals are equipped with the necessary skills and knowledge to execute tasks effectively. A certified installer possesses expertise in various types of piping systems, reducing the likelihood of errors that could lead to costly repairs or complications later on. Their training often includes an understanding of the latest materials and techniques, ensuring that the installation is completed to the highest quality.

In addition to technical proficiency, certified installers can help save time and resources. Their experience means they can anticipate challenges and implement solutions quickly, minimising delays. Furthermore, many certified professionals offer warranties on their work, providing clients with peace of mind. This added layer of assurance reflects their commitment to quality and can prevent future issues arising from poor workmanship in pipe installation and repair.

Implementing Effective Safety Measures

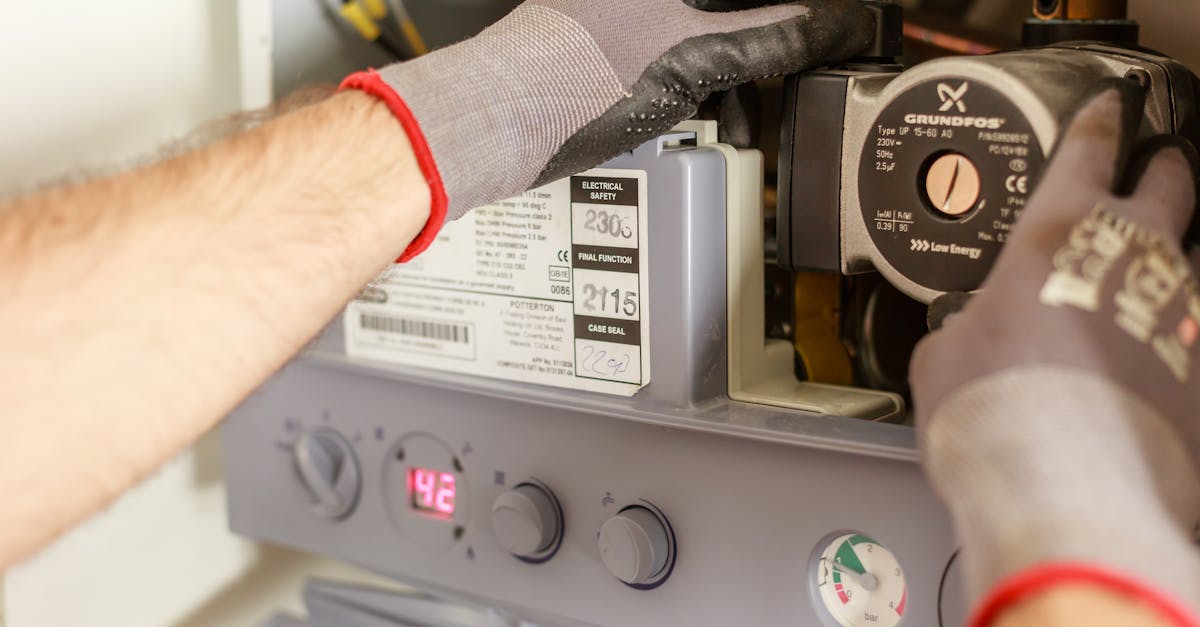

Effective safety measures are essential during pipe installation and repair to ensure compliance with industry standards. This involves understanding the specific risks associated with the materials and environments in which work is conducted. For instance, using appropriate personal protective equipment (PPE) mitigates exposure to hazardous substances and physical hazards. Regular training and drills for all personnel can reinforce these safety practices, creating a culture of awareness around workplace safety.

Additionally, establishing clear protocols helps to streamline the installation process while prioritising safety. Thorough risk assessments should be conducted prior to the commencement of any project. This not only identifies potential hazards but also facilitates the planning of suitable control measures. Another critical aspect is the supervision of work activities to ensure adherence to safety guidelines throughout the pipe installation and repair phases. Implementing these measures significantly reduces the likelihood of accidents and enhances overall project efficiency.

Safety Protocols to Mitigate Risks

A robust framework of safety protocols is essential in any project involving pipe installation and repair. Establishing clearly defined procedures not only ensures compliance with relevant regulations but also fosters a culture of safety among workers. Regular safety training sessions play a crucial role in keeping the workforce updated on the latest best practices and potential hazards associated with pipe installation and repair. This proactive approach helps to minimise accidents and creates a safer working environment.

In addition to training, the use of Personal Protective Equipment (PPE) is vital when carrying out tasks related to pipe installation and repair. Workers should be equipped with the appropriate safety gear, including helmets, gloves, and safety goggles, to safeguard against injuries. On-site safety inspections are also necessary to identify and mitigate risks before they escalate into more significant issues. Maintaining clear communication among team members regarding potential hazards can further enhance safety and ensure everyone is aware of their surroundings.

Avoiding Poor Workmanship

Poor workmanship during pipe installation and repair can lead to significant issues down the line. Inadequate sealing and misaligned fittings are common signs of subpar practices. These mistakes can cause leaks, reduced system efficiency, and unnecessary expenses in both repairs and water loss. Identifying these signs early is crucial to maintaining a reliable and durable plumbing system. Regular inspections can help catch workmanship issues before they escalate.

Another critical aspect to avoid poor workmanship involves understanding and adhering to local codes and standards. Unauthorised alterations or shortcuts during the installation process often result in dangerous situations. Ensuring that installers are following best practices not only guarantees safety but also extends the lifespan of the piping systems. Taking the time to verify that proper techniques are employed is an essential step in ensuring quality outcomes in pipe installation and repair.

Signs of Inadequate Installation Practices

Identifying signs of inadequate installation practices is essential for ensuring the longevity and functionality of plumbing systems. One major indicator is visible leaks at joints or connections, which can compromise efficiency and lead to further damage. Additionally, misaligned pipes can cause stress and strain, increasing the likelihood of future failures. Uneven slopes in drainage systems often lead to water pooling, resulting in potential blockages and costly repairs.

Another critical sign is the use of improper materials or lack of protective measures during installation. Using substandard fittings can lead to premature wear and tear, compromising the entire system. Furthermore, insufficient insulation can contribute to temperature fluctuations and energy loss, impacting overall efficiency. Regular inspections and adherence to standards in pipe installation and repair are essential practices to avoid these issues effectively.

FAQS

Why is it important to involve qualified professionals in pipe installation?

Involving qualified professionals ensures that the installation complies with local regulations and industry standards, reducing the risk of future issues and ensuring safety.

What are the benefits of hiring certified installers for pipe installation?

Certified installers possess the necessary skills, knowledge, and training to perform installations correctly, which can lead to increased efficiency, fewer mistakes, and ultimately, cost savings in the long run.

What safety measures should be implemented during pipe installation?

Effective safety measures include conducting risk assessments, using appropriate personal protective equipment (PPE), and adhering to established safety protocols to mitigate potential hazards.

What are some common safety protocols to mitigate risks during pipe installation?

Common safety protocols include ensuring proper ventilation, following lockout/tagout procedures, maintaining clear work areas, and conducting regular safety training for all personnel involved.

How can one identify signs of inadequate installation practices?

Signs of inadequate installation practices include visible leaks, misaligned pipes, unusual noises during operation, and inconsistent water flow, which can indicate poor workmanship or failure to follow proper installation procedures.