Table Of Contents

Compliance with Industry Standards

Adhering to industry standards is crucial in ensuring the integrity and safety of pipe installation and repair. These standards are established by governing bodies to provide guidelines on materials, methods, and best practices. Compliance not only fosters quality workmanship but also minimises risks associated with improper installations. Stakeholders, including contractors and engineers, must familiarize themselves with the relevant regulations to guarantee that their work meets the expected safety and performance benchmarks.

Regular audits and inspections help maintain compliance with these standards throughout the pipe installation and repair process. By integrating stringent quality assurance measures, companies can reinforce their commitment to delivering reliable and safe infrastructure. Ultimately, a robust adherence to industry standards enhances the reputation of service providers and builds trust with clients and regulatory authorities.

Relevant Codes and Regulations

Compliance with relevant codes and regulations is a fundamental aspect of quality assurance in pipe installation and repair. These guidelines are designed to ensure safety, reliability, and durability of piping systems. Adhering to standards set by organisations such as Standards Australia provides a framework that governs materials, installation practices, and safety protocols. Non-compliance can lead to substandard workmanship, which not only jeopardises the integrity of the installation but also poses significant risks to public safety and the environment.

Regulatory bodies often require that all aspects of pipe installation and repair, including inspections and testing, meet specified criteria. These regulations ensure that installations are performed in a manner that minimises potential hazards associated with leaks and breaks. Regular updates and revisions to codes keep pace with technological advancements and emerging challenges in the industry. Therefore, staying informed about these regulations is crucial for anyone involved in pipe installation and repair.

Training and Skill Development

The effectiveness of pipe installation and repair heavily relies on the skill level of personnel involved in the process. Continuous training programs are essential to ensure workers are familiar with the latest techniques, materials, and safety protocols. These programmes not only enhance individual capabilities but also contribute to overall project efficiency. Equipments evolve rapidly in the plumbing industry, so staying updated through regular courses and workshops is imperative.

Qualified personnel bring a wealth of knowledge to pipe installation and repair tasks. Hands-on experience combined with theoretical understanding ensures that workers can troubleshoot issues effectively and implement best practices. Furthermore, fostering an environment that prioritises skill development can lead to improved job satisfaction and retention rates. Investing in training ultimately leads to higher quality work and mitigates the risk of future complications in plumbing systems.

Importance of Qualified Personnel

Qualified personnel play a critical role in ensuring the success of pipe installation and repair projects. Their expertise not only helps in adhering to established protocols but also mitigates the risk of costly errors. By possessing a deep understanding of materials and techniques, trained professionals can navigate challenges effectively. This level of skill is essential in maintaining the integrity and longevity of piping systems.

Training and certification programs are vital for equipping workers with the necessary knowledge. These initiatives focus on industry standards and best practices, enhancing both safety and efficiency. Investing in qualified personnel fosters a culture of excellence and accountability, which ultimately benefits the overall project outcome in pipe installation and repair.

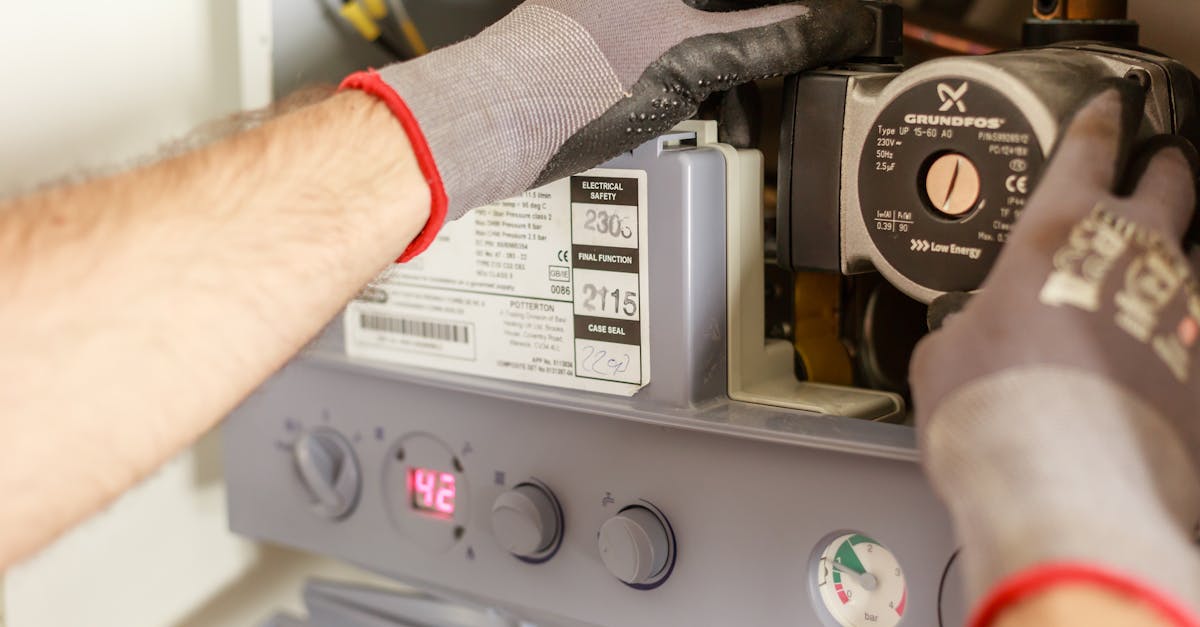

Tools and Technology in Quality Assurance

The integration of advanced tools and technology significantly enhances the process of quality assurance in pipe installation and repair. Utilising cutting-edge equipment, such as ultrasonic thickness gauges and video inspection systems, allows for detailed assessments of pipe integrity prior to installation. These technologies facilitate early detection of potential issues, reducing the likelihood of future repairs. Additionally, software solutions that manage project timelines, materials, and workflow can streamline the process, ensuring all phases comply with relevant standards.

Innovative solutions also play a crucial role in enhancing quality assurance throughout the project lifecycle. Implementing automation and digital monitoring systems can aid in tracking installation progress and assessing compliance with safety regulations. Real-time data collection enables teams to make informed decisions quickly, minimise errors, and optimise workflows. These technological advancements contribute to a more efficient quality assurance process, ultimately leading to more reliable and sustainable pipe installation and repair practices.

Innovative Solutions for Pipe Installation

Advancements in technology have significantly enhanced the methods used in pipe installation and repair. Innovative solutions such as trenchless technology minimise the need for extensive digging, thus reducing disruption and environmental impact. Additionally, the introduction of robotic inspection tools allows for precise assessments of existing pipes, enabling targeted repairs and reducing costs associated with unnecessary excavations. These modern techniques not only improve efficiency but also enhance the overall safety of pipe-related projects.

The integration of smart materials in pipe installation and repair is revolutionising the industry. These materials offer superior durability and resistance to corrosion, contributing to a longer lifespan for pipes. Furthermore, systems incorporating real-time monitoring sensors can detect leaks or weaknesses before they become critical issues. By leveraging these advanced technologies, the effectiveness and reliability of pipe installation and repair processes are greatly enhanced, paving the way for more sustainable infrastructure solutions.

FAQS

Why is quality assurance important in pipe installation?

Quality assurance in pipe installation is crucial as it ensures that the pipes are installed correctly and meet industry standards, which helps prevent future failures, leaks, and costly repairs.

What are the key industry standards for pipe installation?

Key industry standards for pipe installation include relevant codes and regulations set by organisations such as AS/NZS (Australian/New Zealand Standards) which outline specific requirements for materials, safety, and installation practices.

How can training improve the quality of pipe installation?

Training enhances the skills and knowledge of personnel involved in pipe installation, ensuring they are familiar with current industry standards, techniques, and safety protocols, which ultimately leads to higher quality workmanship.

What role do tools and technology play in quality assurance for pipe installation?

Tools and technology play a significant role in quality assurance by providing innovative solutions that improve accuracy, efficiency, and safety during the installation process, thereby reducing the risk of errors and enhancing overall quality.

How can I ensure that my pipe installation is compliant with regulations?

To ensure compliance with regulations, it is essential to engage qualified personnel who are knowledgeable about the relevant codes, conduct thorough inspections, and utilise appropriate tools and technologies throughout the installation process.