Table Of Contents

Training and Certification Requirements

Training and certification are crucial for individuals engaged in pipe installation and repair within New South Wales. Workers in this field must possess specialised skills to ensure safety and effectiveness in their roles. Various training programs offer comprehensive knowledge about the techniques involved, as well as the safety standards mandated by local regulations. Certification not only validates competence but also ensures that workers stay updated on best practices and new technologies.

To be eligible for certification, individuals typically need to complete a recognised training course that covers both theoretical knowledge and practical skills. This training often includes modules on hazard identification, risk assessment, and emergency response procedures related to pipe installation and repair. By emphasising the importance of ongoing training, the industry can foster a workforce equipped to handle complex tasks safely and efficiently.

Ensuring Competence in Installation Practices

Competence in installation practices is essential to ensure the safe and reliable operation of pipe systems. Workers involved in pipe installation and repair must possess the appropriate skills and knowledge to adhere to safety standards and regulatory requirements. This often involves a combination of formal training, practical experience, and ongoing education to keep abreast of new techniques and technologies in the industry. Employers should scrutinise the credentials of their personnel and provide opportunities for further development to enhance proficiency.

To maintain high standards in pipe installation and repair, periodic assessments and audits should be conducted. These evaluations help identify potential gaps in skills and knowledge, enabling teams to implement corrective action where necessary. Regular training sessions and workshops can reinforce best practices and introduce new methodologies. Establishing a culture of continuous improvement not only boosts competence but also enhances overall workplace safety and efficiency.

Procedures for Safe Installation Practices

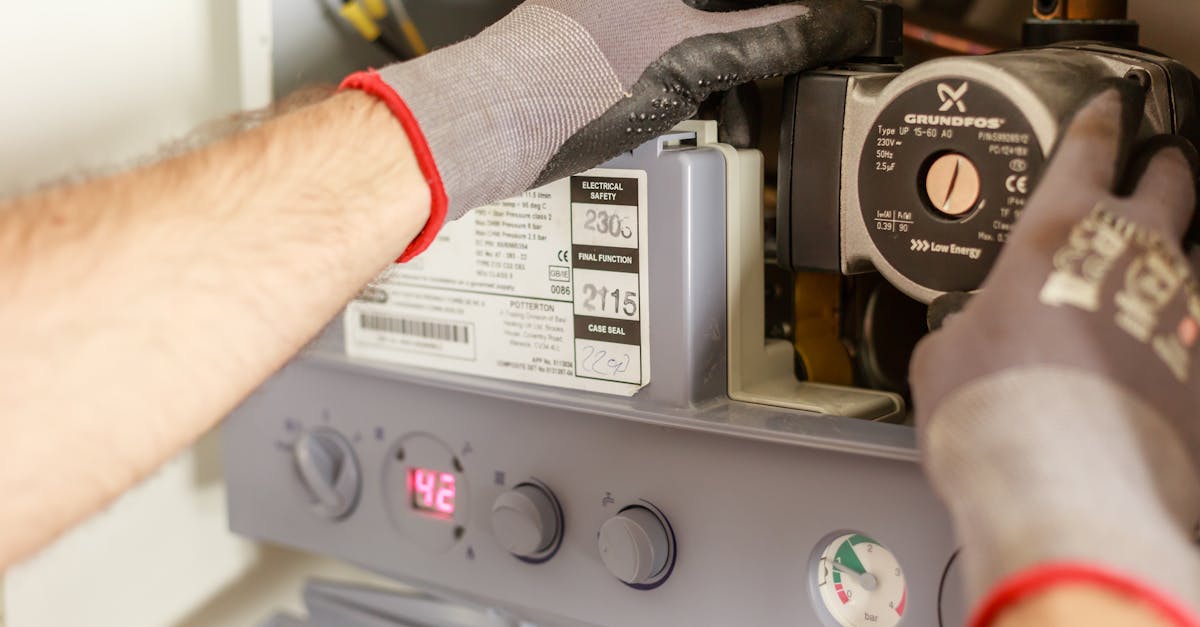

Adhering to set procedures is vital for ensuring the safety of pipe installation and repair. Each installation site should undergo a thorough assessment to identify potential hazards. Proper planning includes determining the correct materials and tools required for the job. Additionally, it is essential to establish a safe working environment. Access to safety equipment and clear communication among team members should also be prioritised.

Following established protocols during pipe installation and repair helps mitigate risks. Workers must be briefed on site-specific procedures, including the proper handling of materials and the use of personal protective equipment. Regular inspections during the process can identify any safety breaches early, allowing for timely corrective actions. It is also imperative to document all procedures followed to ensure compliance with relevant safety standards and regulations.

StepbyStep Guide to Follow

Understanding the intricacies of pipe installation and repair is crucial for successful outcomes. The process begins with thorough planning. Site assessments should be conducted to evaluate soil conditions, existing utilities, and environmental factors. Proper documentation is essential, including blueprints and installation specifications, ensuring that the project adheres to local regulations.

Once the site is prepared, excavation can commence in accordance with safety guidelines. Adhere to the specified depths and widths to prevent collapses or accidental damage to existing structures. After preparing the trench, proper handling of materials is vital to maintain integrity during installation. Regular inspections at each stage allow for adjustments, ensuring that pipe installation and repair are executed with precision and care.

Emergency Protocols for Pipe Installation

Emergency protocols for pipe installation require clear guidelines to ensure safety and swift response during incidents. Teams must be trained in recognising potential hazards associated with pipe installation and repair. Emergency procedures should be readily available on-site to facilitate immediate access in critical situations. Regular drills can enhance preparedness, ensuring that all personnel know their roles and responsibilities during emergencies.

When an incident occurs, the first step is to establish a safe zone for all workers. This area should be free from any potential risks linked to pipe installation and repair. Communication lines must be open, allowing for quick reporting of the situation to supervisors. Prompt assessment of the incident is essential to determine the necessary actions, including whether to evacuate or provide first aid to affected individuals. Proper documentation of the incident plays a crucial role in future safety improvements and compliance with regulations.

Responding to Incidents Effectively

In the event of an incident during pipe installation and repair, it is crucial to follow a well-defined emergency response plan. The first step involves assessing the situation to understand the nature and severity of the incident. Team members should be instructed to remain calm while promptly reporting the issue to the designated safety officer. Communication tools should be readily available to ensure that all personnel are informed of the incident and any potential threats to safety.

Once the situation has been assessed and reported, it is important to initiate emergency procedures. This includes safely evacuating the area, providing first aid to any injured personnel, and coordinating with emergency services if required. Proper documentation of the incident is essential for future analysis and to enhance safety standards in pipe installation and repair processes. All team members should be aware of their roles during such events to ensure a swift and effective response.

FAQS

What are the training requirements for pipe installation in New South Wales?

In New South Wales, individuals involved in pipe installation must complete relevant training programs and obtain certification to ensure they are competent in safe installation practices.

How can I ensure that my installation team is competent?

To ensure your installation team is competent, verify that each member has the necessary training and certifications, and consider conducting regular assessments and refresher courses to maintain their skills.

What are the key steps to follow for safe pipe installation?

Key steps for safe pipe installation include conducting site assessments, following a detailed installation plan, using appropriate personal protective equipment (PPE), and adhering to local regulations and safety standards.

What should I do in case of an emergency during pipe installation?

In case of an emergency during pipe installation, follow your pre-established emergency protocols, assess the situation, ensure everyone's safety, and contact emergency services if necessary. Document the incident for future reference.

Are there specific regulations governing pipe installation in New South Wales?

Yes, pipe installation in New South Wales is governed by various safety standards and regulations, including the Work Health and Safety Act, which outlines the requirements for safe practices and risk management in construction activities.