Table Of Contents

Replacing WornOut Washers and ORings

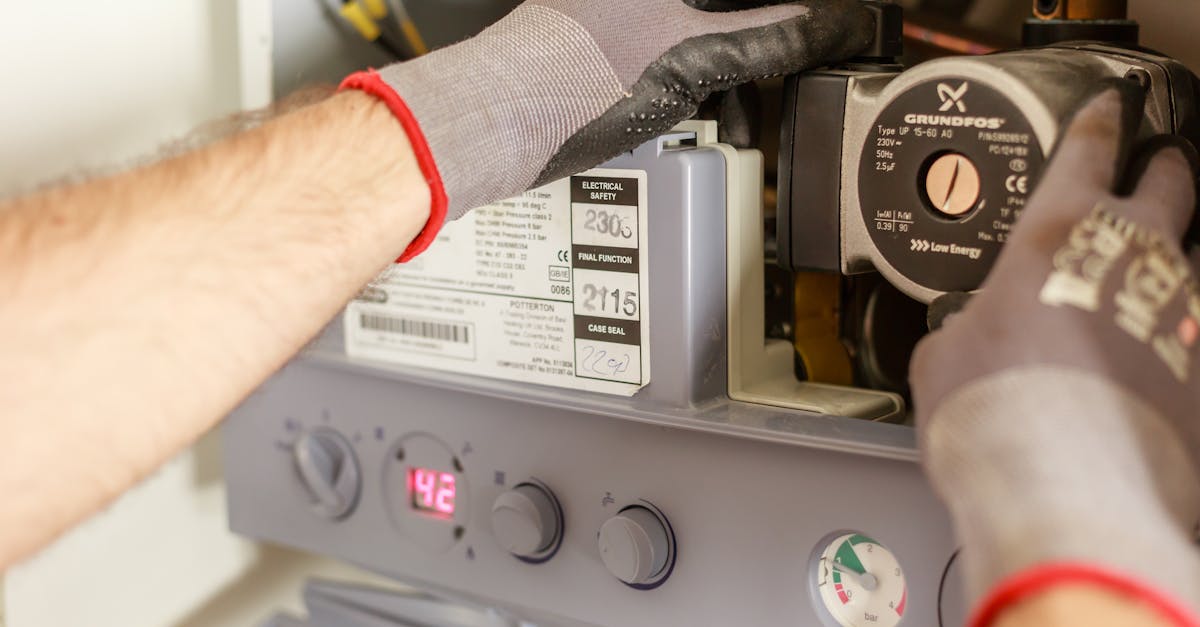

Over time, washers and O-rings in plumbing fittings can wear out due to constant exposure to water and pressure. A deteriorating washer or O-ring often leads to leaks that, if not addressed promptly, can result in water damage and increased utility bills. To replace these components, first ensure the water supply is turned off. Disassemble the fitting carefully and inspect the old washer or O-ring for signs of wear or damage. Once removed, replace it with a new one that matches the size and type of the original.

Pipe installation and repair often requires the right tools to facilitate a smooth replacement process. After installing the new washer or O-ring, reassemble the fitting and turn the water supply back on. Check for leaks after the new components are in place. Regular maintenance, including periodic checks on washers and O-rings, can significantly prolong the life of plumbing fittings and prevent costly repairs down the line.

The Importance of Regular Maintenance

Regular maintenance plays a crucial role in preventing plumbing leaks. Over time, wear and tear can affect fittings, leading to potential leaks that may escalate if not addressed promptly. A proactive approach helps identify problem areas before they develop into major issues, saving both time and money in the long run. This routine upkeep ensures that all components are functioning properly and that there are no underlying concerns with your plumbing system.

In addition to routine checks, a well-maintained plumbing system minimises unforeseen emergencies. Engaging in regular inspections allows homeowners to monitor the condition of fittings, ensuring they are secure and leak-free. This is particularly important in areas where pipe installation and repair may be necessary. By being vigilant about maintenance, you can enhance the longevity of your plumbing system while ensuring it operates efficiently.

When to Use Pipe Joint Compound

Pipe joint compound serves as a crucial application in pipe installation and repair when threading is involved. It provides a seal to threaded connections, preventing leaks that can lead to significant water damage over time. When applying the compound, ensure the threads are clean and free from debris to achieve a proper bond. This step is critical in creating a tight seal that can withstand the pressure of the plumbing system.

Consider using pipe joint compound when working with metal pipes, as the compound aids in filling any gaps that may exist due to imperfections in the threading. It’s important to select a compound designed for the specific type of pipes being used, whether they are PVC, copper, or galvanized. Properly applying the right pipe joint compound can enhance the longevity of your plumbing fittings and help maintain the integrity of your plumbing system.

Applying the Right Sealant for the Job

Selecting the appropriate sealant is crucial for effective plumbing repairs. Various types of sealants are available, each designed for specific applications. For instance, silicone-based sealants excel in flexibility and are often used for joints that may experience movement. Thread sealants work well for threaded connections, providing a reliable barrier against leaks. Understanding the specific requirements for your project will guide you in choosing the right product.

When engaging in pipe installation and repair, it is essential to apply the sealant correctly to ensure a lasting seal. Clean the surfaces thoroughly before application to remove any debris or old sealant. Follow the manufacturer's instructions for curing time and application techniques. This careful approach can significantly reduce the risk of leaks, promoting the longevity of your plumbing system.

Checking for Corrosion in Fittings

Corrosion in plumbing fittings can lead to significant leaks and damage if not addressed promptly. Inspecting various metal components, such as copper, brass, or steel fittings, is essential. Look for signs of rust, pitting, or discoloration. These indicators can suggest that the material has weakened due to prolonged exposure to water and other corrosive elements. Regular checks can help identify issues early, allowing for timely maintenance or replacement, ultimately saving on more extensive repairs down the line.

In the process of pipe installation and repair, taking note of any corrosion can guide your choices for materials and fittings. Choosing corrosion-resistant materials, like PVC or stainless steel, can mitigate future problems. When detected, employing appropriate remedies, such as cleaning or replacing the affected fittings, ensures the integrity of your plumbing system. Implementing these practices not only prolongs the life of your plumbing but also enhances overall home safety and efficiency.

Addressing CorrosionRelated Issues

Corrosion in plumbing fittings can lead to significant leaks and the eventual failure of the system. Addressing these issues promptly is essential to maintain the integrity of your plumbing. Regular inspections of pipes and fittings allow you to identify early signs of corrosion, such as discolouration or rough textures. When corrosion is detected, immediate action is crucial to prevent further damage, which could escalate repair costs.

Replacing affected fittings is often necessary to maintain the overall health of the system. Options like copper or stainless steel can be more resistant to corrosion compared to traditional materials. In cases where minor corrosion is found, applying appropriate sealants may extend the life of the fittings temporarily. However, for lasting solutions, professional assistance in pipe installation and repair should be sought out to ensure compliance with standards and to achieve a reliable plumbing system.

FAQS

What are the signs that my plumbing fittings are leaking?

Common signs of leaking fittings include water stains on walls or ceilings, a damp smell, reduced water pressure, and visible water pooling around the fittings.

How often should I check my plumbing fittings for leaks?

It's advisable to check your plumbing fittings at least once every six months as part of regular maintenance to catch any potential issues early.

Can I fix a leaking fitting myself, or should I call a plumber?

Many minor leaks can be fixed by replacing washers or O-rings, applying sealant, or tightening fittings. However, if you're unsure or the problem persists, it's best to call a plumber.

What types of sealants are recommended for plumbing fittings?

It’s important to use sealants that are specifically designed for plumbing, such as PTFE tape or pipe joint compound, as these will create a watertight seal.

What should I do if I find corrosion on my plumbing fittings?

If you notice corrosion, it’s best to address it promptly. You can clean the affected area with a suitable corrosion remover, but if the fitting is significantly corroded, consider replacing it to avoid further leaks.