Table Of Contents

Installation Practices

Proper installation practices are crucial for maintaining the integrity and functionality of plumbing systems. Plumbers should always adhere to the guidelines set out in the AS/NZS 3500 standards. These codes offer a comprehensive framework that details the correct techniques for pipe installation and repair, ensuring that water flow is efficient and systems remain leak-free. Utilising the right tools and equipment, as specified in the standards, not only enhances the quality of work but also promotes longevity in the installation.

It is essential to consider the environmental factors that may influence plumbing systems. Factors such as temperature changes, soil conditions, and potential ground movement can impact the performance of installed pipes. Therefore, plumbing professionals must assess these elements before commencing any installation work. In addition, ensuring a thorough understanding of the best practices for pipe installation and repair can significantly reduce the risk of future complications, leading to more reliable plumbing solutions.

Best Practices for Plumbers

Plumbers should always adhere to local regulations and standards when performing any work. Understanding AS/NZS 3500 is crucial. This standard provides guidelines on various aspects of plumbing, including installation techniques and materials that are approved for use. Proper training and certification enhance the quality of work and ensure compliance with safety norms. Consistent maintenance of tools and equipment is vital for achieving optimal performance and longevity in pipe installation and repair.

Effective communication with clients is another essential practice. Clear explanations about the scope of work, expected timelines, and potential challenges help in managing customer expectations. Plumbers must also conduct thorough inspections before and after jobs to identify any issues that may arise. Documenting all aspects of the work is beneficial for both the plumber and the client, ensuring transparency and serving as a reference for future maintenance or repairs. By prioritising these best practices, plumbing professionals can deliver high-quality service and build lasting relationships with clients.

Common Materials used under AS/NZS 3500

The AS/NZS 3500 code outlines a range of materials suitable for plumbing and drainage systems in Australia and New Zealand. Copper and PVC are among the most commonly used materials for piping due to their durability and resistance to corrosion. Copper pipes are well-regarded for their longevity and reliability in hot water applications. On the other hand, PVC pipes are lightweight and easy to handle, making them a popular choice for various drainage systems.

In addition to copper and PVC, various types of polyethylene and galvanised steel are also specified in the standards. Polyethylene is often favoured for its flexibility and chemical resistance, which is particularly beneficial in certain environmental conditions. Galvanised steel provides excellent strength and is commonly used in commercial plumbing. Together, these materials ensure that pipe installation and repair meet the necessary regulatory requirements while providing long-lasting infrastructure.

Approved Piping and Fittings

The AS/NZS 3500 standards provide specific guidelines regarding the types of piping and fittings approved for use in plumbing systems. Copper, PVC, and PE (polyethylene) are among the commonly used materials, each with its unique set of properties that cater to various applications. These standards ensure that any materials chosen meet the necessary safety and performance criteria. Compliance with these standards not only ensures durability but also helps prevent potential issues such as leaks and corrosion.

In addition to selecting the right materials, proper installation is critical to maintaining the integrity of plumbing systems. Pipe installation and repair practices must adhere to the specifications outlined in AS/NZS 3500. This includes guidance on jointing methods, alignment, and securing fittings. By following these practices, plumbers can ensure a reliable system that adheres to safety regulations while optimising performance and lifespan.

Safety Considerations

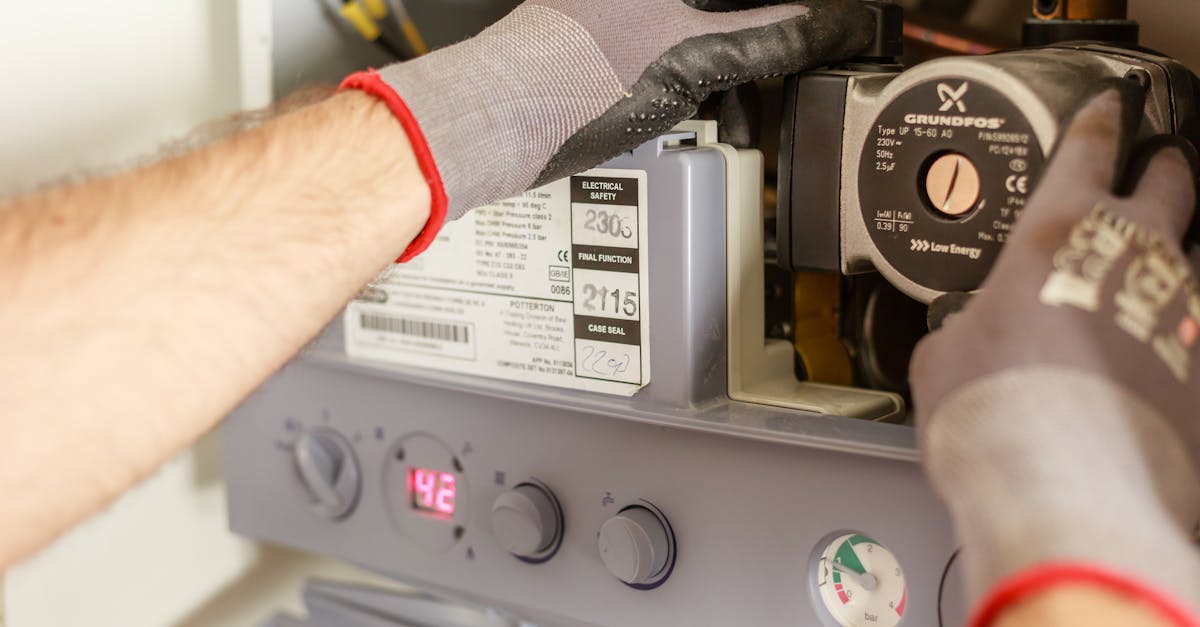

Safety considerations in plumbing are paramount to ensure not only compliance with regulations but also the well-being of both workers and occupants. Proper training in effective methods for pipe installation and repair helps reduce the risk of accidents and injuries. Plumbers must be well-versed in using appropriate personal protective equipment (PPE). This equipment should include gloves, safety goggles, and hard hats, particularly when working in confined spaces or on construction sites.

Compliance with AS/NZS 3500 standards includes ensuring that all safety protocols are observed throughout the installation and maintenance processes. Regular risk assessments should be conducted to identify potential hazards associated with pipe installation and repair tasks. This proactive approach allows for the implementation of safety measures and fosters a culture of safety within the plumbing profession. Prioritising health and safety not only protects plumbers but also safeguards the integrity of plumbing systems in residential and commercial properties.

Ensuring Health and Safety in Plumbing

Health and safety in plumbing is critical to ensuring a safe working environment for both plumbers and the public. Compliance with relevant safety standards significantly minimises the risk of accidents and injuries. A rigorous approach to personal protective equipment (PPE) is essential. This includes the use of gloves, goggles, and appropriate footwear to protect against hazards such as sharp tools and toxic substances. Regular training on safe practices must be undertaken to ensure that all workers are aware of the current regulations and possible risks associated with their tasks.

In the context of pipe installation and repair, proper techniques and the correct handling of materials are crucial. Plumbers must be trained in the safe use of tools and equipment to prevent accidents related to equipment failure or misuse. The work environment should be regularly assessed for potential hazards. This diligence contributes to a culture of safety, where proactive measures are embraced, rather than reactive responses to incidents. Ensuring proper ventilation when working with solvents and ensuring that site conditions are stable cannot be overlooked in promoting workplace safety.

FAQS

What are AS/NZS 3500 standards?

AS/NZS 3500 standards are a set of plumbing and drainage regulations established in Australia and New Zealand, designed to ensure safe and efficient plumbing practices, installations, and materials.

What are the key installation practices outlined in AS/NZS 3500?

The key installation practices include following specific guidelines for pipe installation, ensuring proper drainage systems, and adhering to best practices for maintaining water quality and system efficiency.

What materials are commonly used under the AS/NZS 3500 standards?

Common materials include various types of pipes such as polyvinyl chloride (PVC), copper, and polyethylene, along with fittings that comply with the established standards for durability and safety.

Why is it important to use approved piping and fittings?

Using approved piping and fittings is crucial as it ensures the integrity and safety of plumbing systems, helps prevent leaks and blockages, and complies with regulatory requirements.

How can plumbers ensure health and safety while working?

Plumbers can ensure health and safety by following safety guidelines, using appropriate personal protective equipment (PPE), being aware of potential hazards, and keeping their work area clean and organized.