Table Of Contents

Insurance and Liability Issues

Insurance coverage is critical in mitigating risks associated with pipe installation and repair. Contractors may face significant financial consequences if their work does not comply with established regulations. Insurance policies can vary in terms of coverage, and gaps may occur if non-compliance is identified. Claims related to damages from improperly installed pipes can lead to costly legal disputes, which may not be covered by standard liability insurance. This highlights the importance of thoroughly understanding policy terms and conditions before undertaking a project.

Liability issues can escalate in complex situations where multiple parties are involved in a pipe installation and repair project. Each party may bear responsibility at different stages, making it essential to establish clear contractual obligations. In instances of non-compliance, the liability may not only fall on the contractor but also on engineers and project managers who oversaw the work. Such shared responsibilities can complicate insurance claims and broaden exposure to financial risks, necessitating robust communication and adherence to compliance standards throughout the project lifecycle.

Coverage Gaps Due to NonCompliance

Non-compliance in pipe installation and repair can significantly impact insurance coverage, leading to substantial financial risks for contractors and property owners. Insurance policies often stipulate adherence to regulatory standards. Failure to meet these requirements can result in coverage gaps, leaving stakeholders vulnerable to the financial consequences of property damage or legal claims.

Moreover, non-compliance may also affect the ability to secure future contracts. Clients typically require proof of compliance with relevant standards and regulations. Frequent violations can tarnish a contractor's reputation, diminishing trust and reducing opportunities for securing new work in pipe installation and repair. Rebuilding this trust often necessitates a significant investment of time and resources.

Regulatory Bodies and Their Role

Regulatory bodies play a vital role in overseeing the standards and processes associated with pipe installation and repair. Their mandates typically include setting industry regulations, ensuring compliance, and enforcing safety measures. These entities provide essential guidelines to maintain public health and environmental protection, which are particularly important given the various hazards associated with improper installation. By monitoring compliance and conducting regular inspections, they help mitigate the risks of non-compliance that can lead to significant legal and financial repercussions.

In Australia, several regulatory bodies govern the standards for pipe installation and repair. These include the National Construction Code (NCC) and various state and territory-specific authorities. Each organisation works collaboratively to ensure consistency across the industry while adapting regulations to local needs. Their guidelines address everything from materials and techniques to worker training and safety provisions, reinforcing the importance of professionalism in plumbing and pipe management. It is crucial for contractors to stay informed about these regulations to avoid potential violations that could compromise their work and safety.

Understanding Australian Compliance Enforcers

In Australia, various regulatory bodies oversee the standards related to pipe installation and repair. These organisations ensure compliance with safety, environmental, and quality requirements. They provide guidelines that industry professionals must follow. Compliance with these standards is critical to protect both workers and the environment from potential hazards associated with improper practices.

Local councils and state authorities play pivotal roles in enforcing regulations. They conduct inspections and audits to verify adherence to legal requirements. Non-compliance can lead to significant penalties and shutdowns, putting projects at risk. By understanding the framework established by these compliance enforcers, contractors can mitigate risks and uphold the integrity of their work in pipe installation and repair.

Best Practices for Compliance

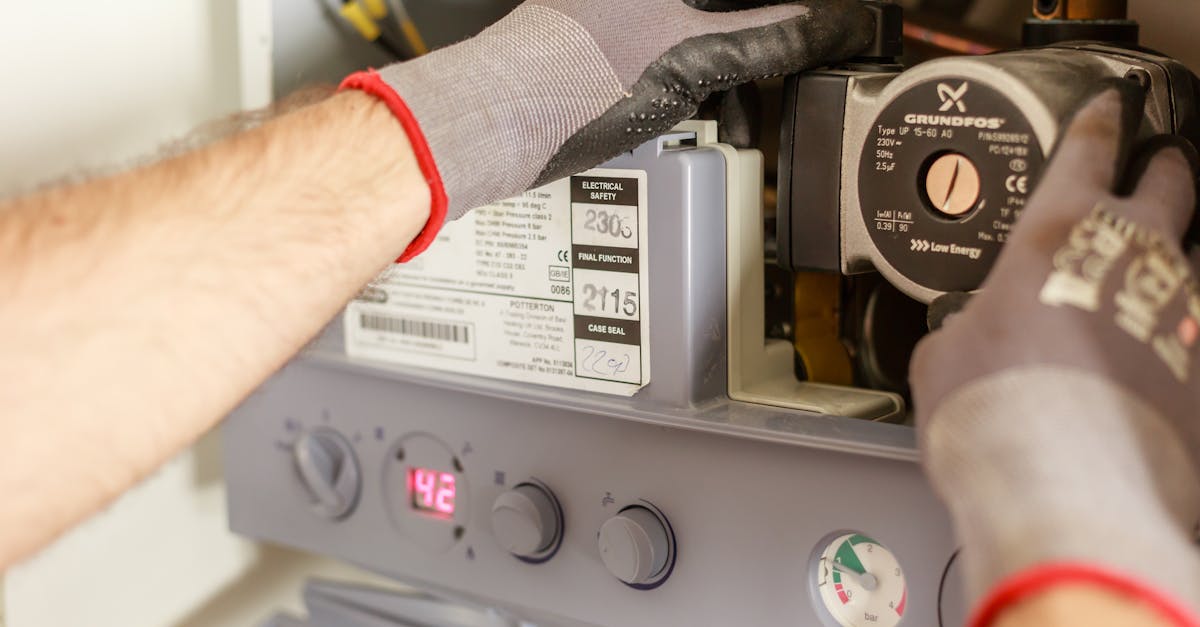

Ensuring compliance in pipe installation and repair demands a proactive approach from all stakeholders involved. Regular training sessions for technicians can significantly enhance awareness of the latest regulations and standards. Implementing checklists before and after installations facilitates adherence to compliance requirements, making it easier to identify potential areas needing improvement. Establishing open lines of communication between teams allows for the swift resolution of compliance-related queries, further strengthening the overall process.

Conducting routine audits of installation practices serves as another key component of maintaining compliance. These audits help identify and rectify any deviations from regulatory standards, thereby minimising risks associated with non-compliance. Keeping meticulous records of all installations creates a traceable history that can inform future projects. Staying updated with any changes to regulations ensures that pipe installation and repair practices remain within legal boundaries, safeguarding both the contractors and clients involved.

Ensuring Adherence to Regulatory Frameworks

Ensuring adherence to regulatory frameworks in pipe installation and repair is essential for meeting industry standards and maintaining safety. Compliance with local and national guidelines not only protects workers but also safeguards the environment from potential hazards. Regular training and updates on regulations for all personnel involved in pipe installation and repair can significantly reduce the risk of non-compliance. This proactive approach fosters a culture of safety and accountability within the workforce.

Utilising proper documentation and maintaining records of all compliance-related activities is vital. These records provide evidence of adherence to regulations and can be crucial during inspections or audits. Engaging with experts in regulatory compliance can assist organisations in navigating complex requirements related to pipe installation and repair. By prioritising compliance, companies can minimise risks and enhance their reputation in the industry.

FAQS

What are the main risks associated with non-compliance in pipe installation?

The primary risks include potential legal liabilities, financial losses, and increased insurance costs. Non-compliance can also lead to safety hazards, environmental damage, and project delays.

How can non-compliance affect insurance coverage?

Non-compliance can create coverage gaps in insurance policies, as insurers may refuse to cover claims related to installations that do not meet regulatory standards. This can leave businesses financially vulnerable in the event of a claim.

What regulatory bodies oversee pipe installation compliance in Australia?

In Australia, regulatory oversight is typically provided by various government bodies, such as Safe Work Australia, state-based Work Health and Safety regulators, and local councils, each enforcing specific compliance standards for pipe installations.

What best practices can be implemented to ensure compliance?

To ensure compliance, businesses should stay informed about relevant regulations, conduct regular training for staff, implement quality control measures, and engage with certified professionals during installation processes.

What should I do if I suspect non-compliance in a pipe installation project?

If you suspect non-compliance, it's important to report your concerns to the appropriate regulatory body or seek advice from a legal professional who specialises in compliance and construction law.