Table Of Contents

Water Management During Pipe Installation

Effective water management during pipe installation is crucial to minimise the risk of contamination and protect local water sources. During the excavation process, measures should be implemented to prevent sediment runoff, which can adversely affect nearby waterways. This may involve the use of sediment fences, silt traps, and other barriers to capture and filter out harmful particles from the site. Additionally, the timing of installation activities should be carefully planned to avoid heavy rainfall periods that could exacerbate water management challenges.

In the context of pipe installation and repair, it is essential to monitor groundwater levels and understand the local hydrology. This ensures that any dewatering activities are conducted responsibly, thereby safeguarding the surrounding ecosystems. Employing techniques such as trenchless technology can significantly reduce the disruption to natural water pathways, limiting potential impacts on the environment. Adopting best practices in water management not only complies with regulatory standards but also promotes sustainable construction practices within the community.

Strategies to Prevent Contamination of Water Sources

Preventing contamination of water sources during pipe installation and repair is crucial for maintaining environmental integrity. One effective strategy involves implementing rigorous site assessments before any groundwork begins. Identifying potential contamination risks in the area allows for tailored mitigation plans. Clear delineation of work zones helps minimise disturbances to surrounding ecosystems and prevents sediment run-off into nearby waterways.

Another critical measure is the use of controlled sediment barriers and erosion control mats around the worksite. These physical barriers catch sediments that may be disturbed during pipe installation and repair, significantly reducing the risk of contaminated runoff. Regular monitoring of nearby water bodies throughout the project also ensures any signs of pollution are detected early. Ensuring proper training for workers on best practices related to waste disposal can further limit the impact on water sources.

Waste Management in Pipeline Projects

Effective waste management is crucial in pipeline projects to minimise the environmental footprint and ensure compliance with regulations. Pipe installation and repair activities often generate substantial waste, including excess materials, packaging, and contaminated soil. Proper waste handling practices should be established from the outset. This includes segregating different types of waste, implementing recycling protocols, and ensuring hazardous materials are disposed of safely. Engaging with waste management specialists can also facilitate the development of strategies tailored to the specific challenges of pipeline projects.

The use of innovative solutions can enhance waste management efficiency during pipeline installation. Technologies such as mobile waste treatment units can process contaminated soil on-site, reducing the need to transport waste to distant facilities. Additionally, adopting a circular economy approach encourages the reuse of materials wherever possible. This practice not only minimises waste but also reduces costs associated with material procurement. Implementing these strategies contributes to more sustainable outcomes in pipe installation and repair, aligning project goals with environmental stewardship.

Effective Recycling and Disposal Methods

Effective recycling and disposal methods are crucial in minimising the environmental impact of pipeline projects. Efficient management of waste materials generated during pipe installation and repair can significantly reduce landfill use. Initiatives such as the separation of materials at the source allow for the recycling of metals, plastics, and other components. Implementing these strategies not only conserves resources but also fosters a circular economy where materials are reused rather than disposed of.

Utilising local recycling facilities can streamline the disposal process and ensure compliance with regulations. Partnerships with waste management companies can facilitate the recycling of surplus or unused materials. In addition to recycling, proper disposal methods must be established for materials that cannot be recycled. This approach ensures that pipe installation and repair projects adhere to environmental standards while minimising harm to local ecosystems.

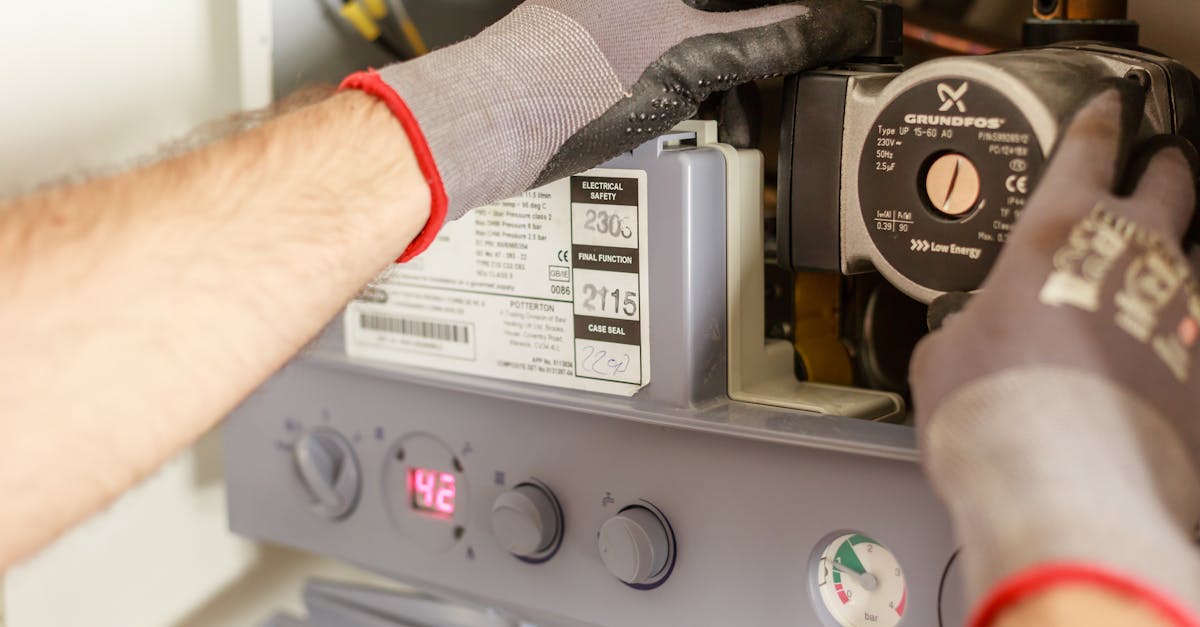

Innovations in Pipe Installation Technology

Recent developments in pipe installation technology have significantly improved efficiency and reduced environmental impact. Trenchless technology, for example, allows for pipes to be installed without the need for extensive excavations. This method minimises soil disruption and reduces the risk of contaminating nearby water sources. Moreover, advancements in pipe materials contribute to longevity and decreased maintenance needs, supporting more sustainable practices in the sector.

Additionally, innovations in monitoring tools enhance the safety of pipe installation and repair projects. Smart sensors can detect leaks and structural weaknesses in real time, facilitating timely interventions. These technologies not only improve the lifespan of pipelines but also prevent potential environmental hazards. Sustainable practices during installation lead to overall better outcomes for both the ecosystem and community wellbeing.

Environmentally Conscious Advancements to Consider

Emerging technologies in pipe installation and repair have made significant strides towards reducing environmental impact. The use of trenchless technology is gaining traction, allowing for the installation of pipes without extensive excavation. This method minimises soil disruption, reduces the risk of water source contamination, and facilitates faster project completion. Additionally, advancements in materials such as bioplastics and composite pipes are proving to be both durable and less harmful to the environment compared to traditional options.

Another innovation in this field is the incorporation of smart monitoring systems. These systems enable real-time tracking of pipeline conditions, detecting leaks or structural issues early. Such proactive measures not only enhance the longevity of installations but also prevent potential environmental damage caused by unaddressed failures. By embracing these advancements, the industry moves towards more sustainable practices while addressing the essential needs of infrastructure development.

FAQS

What are the key environmental concerns during pipe installation?

Key environmental concerns during pipe installation include the potential contamination of water sources, disruption of local ecosystems, waste generation, and the carbon footprint associated with the installation process.

How can contamination of water sources be prevented during pipe installation?

Contamination of water sources can be prevented by implementing strategies such as proper site assessments, using barriers and diversion techniques, ensuring effective spill response plans, and employing environmentally friendly materials and methods.

What waste management practices should be followed in pipeline projects?

Waste management practices in pipeline projects should include reducing waste generation, recycling materials wherever possible, safe disposal of hazardous waste, and ensuring that all waste is managed in compliance with local regulations.

What are some innovative technologies in pipe installation that consider environmental impact?

Innovative technologies include trenchless installation methods, which reduce surface disruption, the use of biodegradable or recycled materials for pipes, and advancements in monitoring systems that help manage environmental risks during installation.

Why is it important to consider environmental factors in pipe installation standards?

It is important to consider environmental factors in pipe installation standards to protect natural resources, minimise ecological impact, comply with regulations, and promote sustainable practices within the industry, ultimately contributing to the long-term health of the environment.