Table Of Contents

The Role of Technology in Inspections

Technology has significantly transformed the landscape of inspections in the field of pipe installation and repair. Advanced tools such as drones and robotic crawlers allow for in-depth analysis of hard-to-reach areas, increasing the accuracy and efficiency of inspections. These innovations enable real-time monitoring and data collection, which facilitate prompt decision-making and eliminate the need for extensive manual checks that can be time-consuming and labour-intensive.

Additionally, software solutions have emerged that support inspectors in mapping out inspection schedules, managing data, and generating reports with ease. This integration of technology streamlines workflows and enhances communication among team members, ensuring that everyone has access to the most up-to-date information regarding pipe conditions. By leveraging these technological advancements, organisations can maintain higher standards of compliance throughout their pipe installation and repair processes.

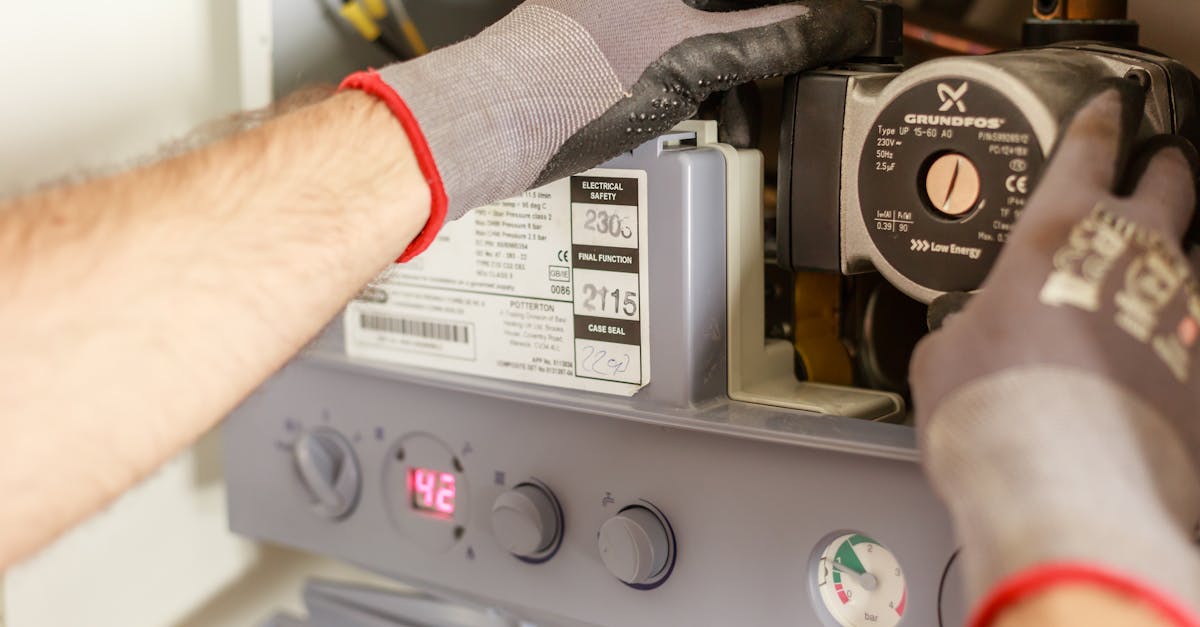

Innovative Tools and Techniques used

Recent advancements in technology have introduced innovative tools and techniques that significantly enhance the inspection process. Non-destructive testing methods, such as ultrasonic testing and infrared thermography, allow inspectors to assess the integrity of pipelines without causing any damage. These techniques enable the detection of flaws and weaknesses, ensuring that compliance with pipe standards is maintained throughout the lifecycle of the infrastructure. In addition, drones equipped with high-resolution cameras can conduct aerial surveys of hard-to-reach areas, streamlining the inspection process considerably.

For pipe installation and repair, the incorporation of digital technologies like 3D modelling and augmented reality has transformed how inspectors evaluate projects. These tools provide visual representations of pipelines, allowing for comprehensive assessments that can identify potential issues before they escalate. Furthermore, the use of mobile applications enables real-time reporting and data collection, enhancing the efficiency of inspections and ensuring timely compliance monitoring. Such innovative approaches contribute to a more systematic and proactive strategy in maintaining high standards within the industry.

Benefits of Regular Inspections

Regular inspections play a critical role in maintaining high standards for pipe installation and repair. They help to identify potential issues before they escalate into significant problems that could compromise safety and efficiency. These inspections ensure that work adheres to industry regulations and specifications. By conducting thorough evaluations, organisations can mitigate risks associated with leaks or structural failures in piping systems.

In addition to enhancing safety, routine inspections can extend the lifespan of pipes. Regular assessments allow for timely maintenance and repairs, which can prevent costly replacements in the future. Furthermore, consistent monitoring provides valuable data that can inform best practices in pipe installation and repair, fostering continuous improvement in operational processes.

Enhancing Safety and Efficiency

Regular inspections play a crucial role in enhancing both safety and efficiency during pipe installation and repair processes. By identifying potential issues early on, such as faulty materials or improper fittings, inspectors can prevent accidents before they occur. This proactive approach not only safeguards workers on-site but also minimises the risk of costly downtime that can arise from unexpected pipe failures.

Furthermore, inspections ensure compliance with established pipe standards, which is vital for maintaining operational integrity. Effective monitoring of installation practices translates into stronger pipelines and reduced likelihood of leaks or failures in the future. Adhering to best practices reinforces a culture of safety and accountability, ultimately benefiting both personnel and the broader community in which they operate.

Training for Inspection Personnel

Training for inspection personnel is critical to ensure they possess the necessary skills to uphold compliance with pipe standards. A robust training programme equips inspectors with knowledge of the latest regulations, safety guidelines, and technological advancements relevant to pipe installation and repair. This foundational understanding enables them to identify potential issues or non-conformities during the inspection process.

Furthermore, hands-on experience plays a significant role in effective training. Simulation-based exercises help inspection personnel develop practical skills in evaluating pipe structures and detecting flaws. By engaging in real-world scenarios, inspectors can learn the intricacies of pipe installation and repair, ensuring they are well-prepared to meet industry demands and uphold stringent quality standards.

Skills Required for Effective Compliance Monitoring

Effective compliance monitoring in the context of pipe installation and repair demands a specific skill set from inspection personnel. A solid understanding of relevant regulatory frameworks, such as Australian standards for piping systems, is crucial. Inspectors need to be proficient in interpreting technical specifications and industry guidelines. Additionally, familiarity with the various materials and technologies used in pipe installation ensures accurate assessments during inspections.

Attention to detail plays a significant role in ensuring compliance. Inspectors must be adept at identifying potential defects or deviations from prescribed standards. Strong analytical skills allow them to evaluate complex systems and make informed decisions about required corrective actions. Furthermore, excellent communication skills are essential for reporting findings clearly to stakeholders and facilitating discussions on compliance issues related to pipe installation and repair.

FAQS

Why are inspections important for ensuring compliance with pipe standards?

Inspections are crucial as they verify that pipes meet safety and quality standards, preventing potential hazards and ensuring reliable performance in various applications.

What types of technology are commonly used in pipe inspections?

Common technologies include ultrasonic testing, magnetic particle testing, and visual inspection tools, which enhance the accuracy and efficiency of the inspection process.

How often should pipe inspections be conducted?

The frequency of inspections depends on various factors such as the type of piping system, industry regulations, and the potential risks involved. Regular assessments are recommended to maintain compliance and safety.

What skills are necessary for inspection personnel?

Inspection personnel should possess technical knowledge of pipe standards, familiarity with inspection tools, attention to detail, and strong analytical skills to evaluate compliance effectively.

What are the benefits of regular inspections beyond compliance?

Regular inspections enhance safety, extend the lifespan of piping systems, reduce maintenance costs, and improve operational efficiency, ultimately leading to a safer working environment.